Custom

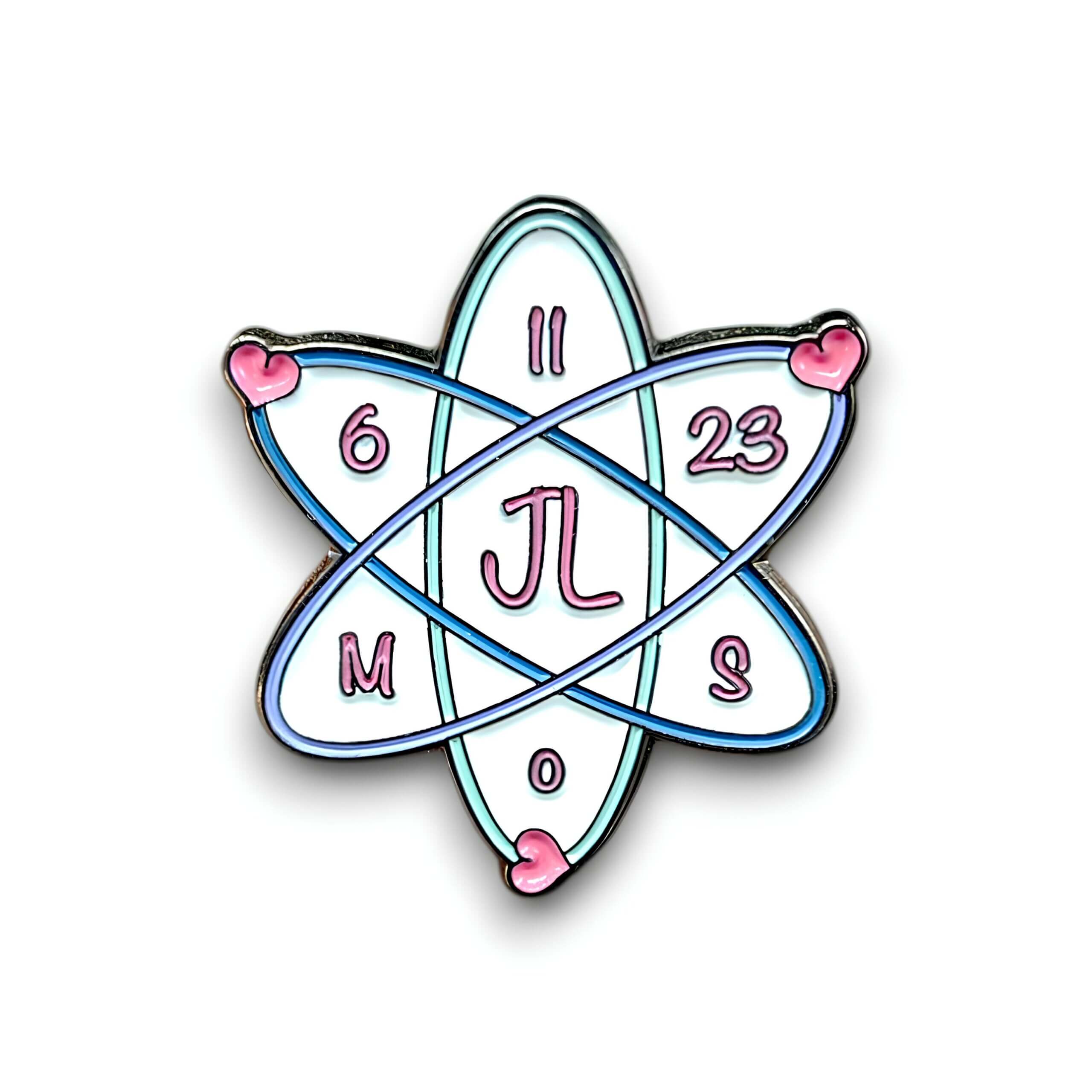

Soft Enamel Pin

Whether you’re a business looking to expand your product line, a pin collector creating a custom piece, or an organization planning a memorable event, we’ve got you covered.

Details

Minimum Order Quantity – 30 pieces per design.

Product Thickness – 1.5mm for a solid, premium feel.

Material – Made from iron or zinc alloy, depending on the design’s specifications.

Enamel Colors – Pricing is based on the number of colors in your design. Our team will confirm the exact count based on your artwork.

Customizations – Customize your order with backer cards, packaging, laser engraving, special effects, and back stamps. Contact us at pin@blythemetalbadge.com to discuss your preferences.

Artwork

File Type – Vector preferred, all formats accepted.

Plating Options – Details available here.

Enamel Color Matching – Full color guide available upon request.

Special Effects – Available effects include glitter, glow-in-the-dark, and more. See our guide for options.

Production/Shipping Time

Average Production Time – 2-3 weeks after proof approval.

Average Transit Time – 3-5 business days.

For more questions, please visit our FAQ page.

How To Make Soft Enamel Pins?

Submit Your Design

Send us your artwork with size, color, and finish details. We’ll create a digital proof to match your vision.

Proof & Sampling

Review your proof or request a sample before full production. We ensure every detail is perfect.

Production & Delivery

Once approved, we manufacture and ship your custom soft enamel pins within 2-4 weeks.

Pin Plating

Back Attachments

Enhancement

Pin Packaging

All About Soft Enamel Pins

Soft enamel pins are known for their textured, layered feel. The metal lines are raised, and the enamel colors sit slightly lower, creating a distinct, tactile surface. This gives the pin a bold, detailed appearance that stands out.

Thanks to their simpler production process, soft enamel pins are more affordable than hard enamel pins. They’re a popular choice for logos, name badges, and custom designs where a vibrant, classic enamel pin look is desired without the higher cost.

⭐ Soft enamel vs hard enamel pins: Soft enamel offers a more textured look, while hard enamel has a smooth, polished finish — both are durable and stylish.

Try Before You Decide

Unsure about a new effect? We offer sample production so you can see how your design will look before committing to the full order.

Your design is yours alone. We guarantee that we never resell your artwork, and we retain your mold for up to 3 years—so if you need to reorder, we can easily provide your custom soft enamel pins again.

Guidance for First-Time Pin Makers

If you’re new to pin-making, don’t worry! Our team is here to guide you through every step of creating your custom soft enamel pins, offering professional advice to ensure your final product is exactly what you want.

What clients say

Testimonial

FAQs

Frequently asked questions

We are here to help you 7 days a week and respond within 24 hours.

Need more information? Check out our full FAQ page here.

What is the difference between soft enamel and hard enamel pins?

The primary difference lies in texture and finish. Soft enamel pins have a textured surface with raised metal edges and recessed enamel areas, while hard enamel pins are polished to a smooth, flat finish where the enamel is level with the metal edges. Additionally, hard enamel pins are typically more durable and scratch-resistant.

What is the minimum order quantity for custom soft enamel pins?

At Factorypin, we offer a minimum order quantity of 30 pieces, accommodating both small and large orders to meet your specific needs.

How does Factorypin protect my custom design?

At Factorypin, we prioritize the confidentiality and exclusivity of your designs. We implement strict measures to ensure your intellectual property remains secure and is not used without your explicit consent. Your design will never be replicated or sold to others, safeguarding your unique creation.

Can I receive the mold used for my pin production?

Yes, upon request, we can provide you with the mold used in your pin production. This ensures that you have full ownership and control over the tools used to create your custom pins.