How to Make Your Own Enamel Pin?

Step-by-step Guide

Creating your own enamel pin is easier than you think. Whether it’s for merch, events, branding, or your personal collection, this guide walks you through every essential step—from artwork to production to choosing the right manufacturer. Use these shortcuts, templates, and factory insights to avoid mistakes and get your custom enamel pins made exactly the way you imagine.

Step 1:

Prepare Your Design Files

Your artwork is the foundation of a great enamel pin.

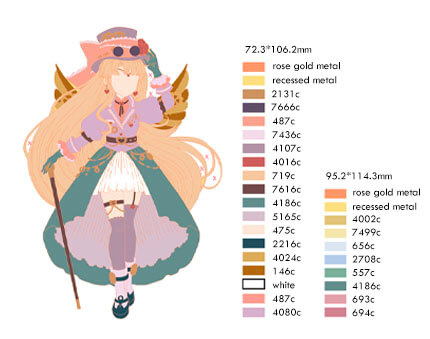

If you already have a design, make sure it’s saved in vector format (.AI, .PDF, .EPS). Vector files keep lines sharp and ensure accurate metal outlines during mold making.

No artwork yet? You can sketch it, hire an artist, or use templates—but keep shapes clean and avoid extremely thin lines. Enamel pins look best with bold outlines and clear color blocks.

If you need help getting started, check out our guide on how to design enamel pins even if you can’t draw.

If you’re unsure whether your design is enamel-friendly, send it to us—we’ll adjust stroke width, spacing, and color zones so it can be produced smoothly.

Step 2:

The Back Matters Too

| Pin Size | Recommended Pin Backs | Reason |

|---|---|---|

| < 1 inch | 1 | Generally sufficient |

| 1–1.5 inch | 1–2 | Prevents rotation |

| > 1.5 inch | 2–3 | Prevents tilting |

Most people focus on the front, but the back determines:

-

Whether your pin rotates

-

Whether it falls off

-

How stable larger pins are

-

Whether you can add a logo or edition number

Optional Back Features

Backstamp (logo)

Numbering for limited editions

Rotating back or safety pin for oversized badges

- Unique backing card for branding

Step 3:

Soft Enamel?

Hard Enamel ?

These are the two main enamel pin styles:

-

Raised metal lines, recessed color

-

Rich texture and depth

-

Great for bold illustrations and high contrast designs

-

Smooth, polished surface

-

Premium and durable

-

Perfect for logo pins, gifts, or daily-wear pins

Step 4:

Pin Plating Options

Plating defines the metal color of your enamel pin and affects the entire look and feel.

Factory Tip

- Avoid black nickel for large flat surfaces—it scratches easier.

- If your design includes texture or shading, antique plating gives the best depth.

Step 5:

Budget, Quantity & Timeline Planning

Enamel pin pricing depends on:

-

Pin size

-

Hard vs. soft enamel

-

Number of colors

-

Plating

-

Special effects (glitter, glow, transparent enamel, UV print)

-

Packaging

-

Quantity

| Factor | Effect on Cost | Factory Advice |

|---|---|---|

| Enamel Type | Hard enamel > Soft enamel | Use soft enamel for small runs; hard enamel for polished finish and durability |

| Size & Complexity | Larger/more detailed pins cost more | Simplify tiny elements where possible |

| Colors & Effects | More Pantone colors or effects increase cost | Consolidate similar colors across designs or skip non-essential effects |

| Quantity | More units reduce per-pin cost | Ask if similar designs can share molds to save on setup fees |

| Packaging | Custom backing cards or boxes add cost | Design versatile packaging usable for multiple pin designs |

Factory Tip

- Align your timeline with production lead times (typically 2–4 weeks).

- Confirm designs and payment early to avoid delays.

- Rush orders are possible, but additional fees apply.

Step 6:

Choosing Your Manufacturer

Your enamel pin manufacturer determines 70% of the final result.

Look for factories that offer:

-

Clear artwork review

-

Accurate Pantone color-matching

-

Professional mold making

-

Stable plating quality

-

Fast sample confirmation

-

Low defect rates

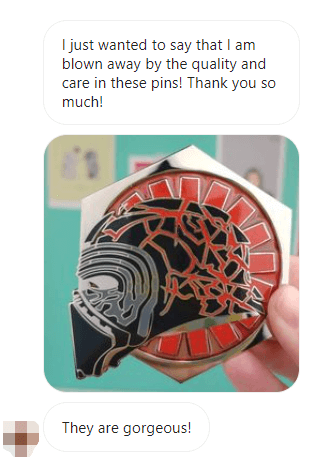

That is why we recommend working with Factorypin. We save molds for 2–3 years, offer a wide variety of custom options, and keep you updated on your production progress. With a 70% repurchase rate, our customers trust us to deliver high-quality enamel pins every time.

If you have any questions during your custom pin process, feel free to contact us—we’re happy to provide professional guidance.