Enamel pins are everywhere these days – jazzing up backpacks, denim jackets, and even the occasional lapel. They may be small, but behind every pin is a carefully controlled manufacturing process that turns a simple design into a durable, collectible product.

So how are enamel pins actually made?

Whether you’re planning to create custom pins for a brand, event, or collection, understanding the process helps you make better design choices and avoid costly mistakes. Let’s break it down step by step!

1. Design & Specs: Where the Magic Begins (and Sometimes Goes Wrong)

Every enamel pin starts with a brilliant idea (or sometimes, a not-so-brilliant one, but hey, we’ve all been there). This is where you, as a distributor, need to work closely with your clients to nail down the perfect design.

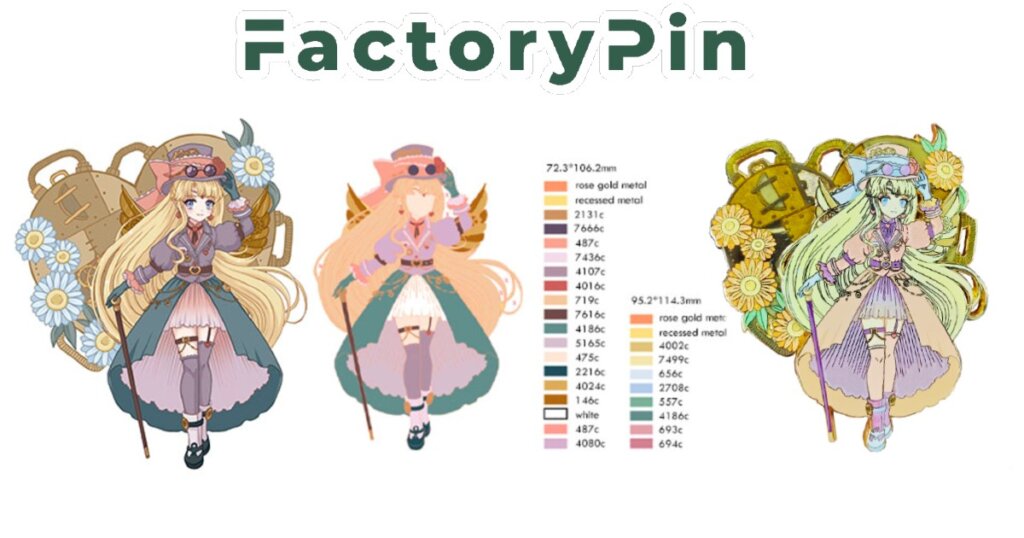

Software & File Formats: Adobe Illustrator and CorelDRAW are your best friends here. Vector files (AI, EPS) are a must – nobody wants a pixelated pin! If you are familiar with procreate or PS or other common artdrawing softwares.

Color Palette: Think of your pin as a tiny canvas. Will it be a vibrant explosion of color or a subtle, sophisticated masterpiece? Pantone Matching System (PMS) is the industry standard for color accuracy, so get familiar with it.

2. Manufacturing Process: From Metal Sheet to Mini Masterpiece

This is where the magic (and a bit of elbow grease) happens! Let’s break down each step:

Mold Types and Materials:

In actual production, enamel pin molds are created using two main methods: stamping molds and casting molds.

- Iron and copper pins are typically produced using stamping molds. This method is suitable for flat designs and standard shapes with relatively even depth.

- Zinc alloy pins are produced using a casting process. Casting allows for deeper reliefs, curved surfaces, and more complex structures, making zinc alloy the preferred material for intricate or irregular designs.

For designs that require a sandblasted background, this texture is created directly during the mold-making stage. The sandblast effect is built into the mold itself, ensuring a consistent matte finish rather than being added later as a surface treatment.

Stamping:

During stamping, a metal sheet is pressed into the mold under controlled pressure to form the pin shape. Proper pressure calibration is critical: insufficient pressure can cause incomplete edges, while excessive pressure shortens mold life and may introduce deformation. These issues are common in low-cost production environments.

Cutting & Shaping:

Excess Removal: After stamping, excess metal is trimmed away. This is often done manually with specialized tools. Skilled workers use nippers and files to carefully remove the excess metal, ensuring clean edges.

Edge Finishing: The pin’s edges are then smoothed and polished to prevent any sharp or rough areas. This step can be done by machine or by hand, depending on the desired level of finish. Hand-finishing is often preferred for high-end pins to ensure a perfectly smooth and polished edge.

Plating:

Electroplating: Electroplating adds both visual appeal and corrosion resistance to enamel pins. Common finishes include gold, silver, and nickel. After plating, factories typically apply a thin layer of protective oil to prevent oxidation during handling and storage.

Plating Risk Considerations: More complex plating options—such as rose gold, black nickel, or chrome finishes—carry higher production risk, particularly when applied over large surface areas. Uneven coverage and color inconsistency are more likely compared to standard platings.

For designs with large exposed metal sections, traditional finishes like gold, silver, or nickel are generally safer and more stable choices in mass production.

Enamel Filling & Curing

Color Matching and Application:

Enamel colors are matched strictly against PMS references. Precision during filling is essential, as overfilling or underfilling can affect both appearance and durability.

Soft vs. Hard Enamel Curing:

- Soft enamel pins are filled with all colors first and then cured together in an oven.

- Hard enamel pins follow a different process: each color is applied and cured individually before the next color is added.

This step-by-step curing process is one of the main reasons hard enamel pins require longer production times and are generally more expensive than soft enamel pins.

Before curing, many factories use a brief flame-torch process to remove tiny dust fibers and air bubbles that may enter during filling. This results in brighter, more even, and visually cleaner enamel surfaces.

Polishing:

Polishing serves different purposes depending on the enamel type.

- For soft enamel pins, polishing is usually done before coloring—or sometimes skipped entirely. The goal is mainly to smooth metal lines and remove sharp edges.

- For hard enamel pins, polishing is essential and occurs after curing. Excess enamel is removed to reveal clean, shiny metal lines.

It’s common for customers to feel concerned when seeing hard enamel pins before polishing, as the surface may appear uneven or dull. After polishing, however, the colors become vibrant and the metal lines sharp and glossy, often transforming the overall appearance dramatically.

Backing Attachment:

Backing Options: Butterfly clutches, rubber clutches, magnetic backs, safety pins – the choice depends on the intended use of the pin. If you have questions about how to choose the right pin attachement, you can find the answer in this blog post.

Pin posts are attached to the back of enamel pins using either welding or industrial adhesive bonding. Neither method is universally better; the choice depends on the pin’s material and structure.

In some designs, welding is not feasible, making adhesive bonding the only practical option. If maximum strength is required, welded pin posts are generally preferred, and this requirement can be communicated to the factory in advance.

3. Quality Control: Because Nobody Wants a Wonky Pin

Quality inspection typically includes checking enamel surfaces for scratches or defects, verifying metal lines are clean and undamaged, ensuring plating coverage is complete, and confirming that any special finishes match the approved artwork. Even minor inconsistencies can significantly affect the final appearance, especially in large production runs.

4. Working with Manufacturers: Making Friends (and Pins)

Selecting a reliable manufacturing partner is essential for consistent quality and smooth production. An experienced factory can identify design risks early, maintain stable processes, and communicate clearly throughout the project.

If you are planning to produce custom enamel pins or are ready to start a new order, we strongly recommend that you cooperate with us. At Factorypin, we specialize in enamel pins and other custom metal products for international customers, focusing on careful craftsmanship, efficient production, and long-term cooperation. Our approach has resulted in a repeat order rate of around 70%, reflecting the trust built through consistent quality and reliable service.